EndoTherm – Energy Saving and Carbon Emission Reducing Heating System Additive

EndoTherm is a unique, multi-award winning energy saving additive independently proven to save up to 15% on space heating energy consumption.

Scalable to work in any small or large wet heating system, EndoTherm delivers savings for both domestic and commmercial users.

-

- Due to the surface tension of fluid and imperfections in materials inside heating systems optimal thermal contact is not made.

- When dosed EndoTherm stably changes the surface tension of the fluid by over 60% whilst remaining non-corrosive.

- This increases the thermal contact which improves heat transfer rate and efficiency.

- Resulting in rooms reaching determined temperature quicker and staying warmer for longer.

- Return water temperature is lower which allows boilers to condensate more efficiently and recover more latent heat.

- Less fuel is consumed to maintain thermostatically set temperature.

The Science

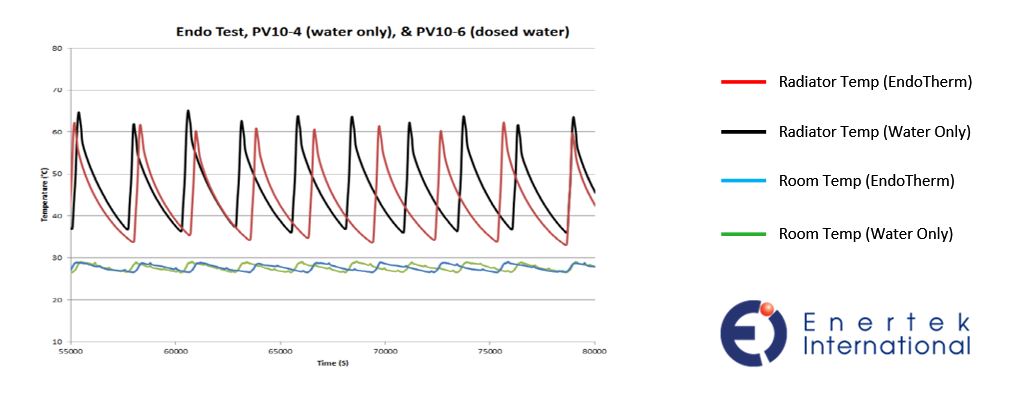

Consider the established methods of improving heating system efficiency. For example ‘Powerflushing’ improves thermal contact area by removing sludge and scale, ‘inhibitors’ prevent this scale from formulating thus maintaining an optimum contact area. EndoTherm too creates a larger thermal contact area on the inside of radiators/AHU chemically (not physically) by reducing the surface tension of the water in any heating system.

Changing the surface tension of heating system fluid essentially makes it “wetter”. EndoTherm breaks down the Hydrogen bonds within the fluid resulting in a 60% “wetter” fluid when compared with standard water. A wetter fluid can access and improve contact with the micro-cracks and unavoidable imperfections within a radiator, boiler tube or heat exchanger. Increased thermal contact improves the efficiency of heat transfer into a building.

As more heat is lost into the room, the water in the system has less energy and returns to the boiler cooler. This cooler return allows modern boilers to condensate more and recover more latent heat from the water reducing the workload of the boiler to heat back up again. This means that even the most modern and energy efficient systems with EndoTherm can use less fuel to maintain the desired or thermostatically set temperature when compared with water only systems